Insulator Hardware in India

Damiano designs and manufactures high-performance insulator hardware in India for overhead transmission and distribution lines. From ball & socket assemblies and tongue & clevis links to yoke plates and arcing horns, our fittings are engineered for strength, corrosion resistance, and long field life—validated through type and routine testing.

Why Insulator Hardware Quality Directly Influences Grid Reliability

Insulators isolate live conductors from towers and poles, but it’s the hardware fittings that transfer mechanical loads, maintain clearances, and hold strings together under wind, ice, heat, and vibration. A small defect in a socket, pin, or clevis can escalate into flashovers, snapped conductors, and costly outages. That is why utilities and EPCs demand fittings with verified KN load ratings, controlled chemistry, and consistent galvanizing.

Damiano’s Manufacturing Edge

1) Materials & Metallurgy

We select the right base material for each duty: SG iron and ductile grades for impact toughness, forged carbon steel for high tensile strength, and aluminium/Al-alloys where weight reduction matters. Every heat is traceable; chemical composition is verified to ensure compatibility with hot-dip galvanizing (HDG) and to avoid hydrogen embrittlement risks.

2) Precision Forging, Casting & CNC Finishing

Critical load-bearing parts are forged for superior grain flow and fatigue life. Complex geometries are delivered via controlled casting with modern gating/feeding simulation. CNC finishing guarantees pin diameters, ball radii, grooves, and hole tolerances that match mating insulator hardware standards for reliable interchangeability on site.

3) Surface Protection & Corrosion Control

All exposed steel parts are hot-dip galvanized with coating thickness checked via magnetic gauge and verified by mass gain. For coastal/industrial atmospheres, we offer duplex systems (HDG + topcoat) to extend life. Aluminium parts receive appropriate anodic protection or sealing as per project need.

Compliant with IS & IEC Standards

Damiano fittings are engineered and tested in line with IS 2486 (insulator fittings) and IEC 61284 (overhead line fittings—requirements and tests). Where project specs demand, we also align with relevant IS/IEC for mechanical load tests, impact tests, slip tests, ultimate tensile strength, and salt-spray or Kesternich corrosion evaluations.

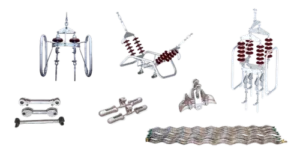

Our Core Insulator Hardware Range

- Ball & Socket fittings (45–210 KN): caps, sockets, ball studs, W-clips for disc insulators.

- Tongue & Clevis links for suspension/tension strings.

- Yoke plates and spacer plates for multi-disc strings.

- Arcing horns and grading rings for improved voltage distribution.

- U-bolts, shackles, eye/eye & eye/clevis links for string configuration flexibility.

- Post/pin insulator end fittings (top, bottom, tie, stay hardware).

Typical voltage applications include 11 kV, 33 kV, 66–132 kV, 220 kV, 400 kV, and up to 765 kV, with KN ratings sized for the specific corridor loads and safety factors.

Testing & Quality Assurance

Each project follows a documented Inspection & Test Plan (ITP). Representative fittings undergo type tests (e.g., tensile proof, ultimate load, slip, bending) and production lots receive routine tests. HDG thickness, adhesion, and uniformity are checked; threads are gauged; critical radii and hole centres are measured with calibrated instruments. Certificates of conformity and test reports can be provided for client records.

How to Specify Insulator Hardware for Your Project

- Voltage Level & System: define kV class, pollution level, and basic insulation level (BIL).

- Mechanical Load: specify working and ultimate KN, wind/ice, span length, and ruling span.

- Material & Finish: forged steel vs. SGI; HDG thickness or duplex needs for coastal/industrial zones.

- Interface Standards: ball sizes, pin diameters, spacing, and interchangeability requirements.

- Documentation: drawings, QAP/ITP, and acceptance tests (FAT/third-party where required).

Share your route conditions and string configuration and our engineering team will help you finalize the Bill of Materials (BOM) with the right safety margins.

Why Choose Damiano

Reliability: Proven designs used by utilities and EPCs across India.

Engineering Support: Application guidance from survey to commissioning.

Speed: Agile production with predictable lead times.

Value: Lifecycle cost advantage via robust design and corrosion protection.

Frequently Asked Questions

What is the difference between ball & socket and tongue & clevis?

Ball & socket is common for disc insulator strings due to quick coupling and universal articulation. Tongue & clevis is preferred where axial alignment control and easy pin inspection are priorities.

How do I choose the KN rating?

Start from the maximum expected mechanical load (wind, ice, angle, span) and apply the safety factor mandated by your utility standard. We will help map loads to hardware ratings and string geometry.

What about corrosion in coastal areas?

Use higher HDG thickness and consider duplex coating (HDG + paint). Stainless options or aluminium alloys may be evaluated for specific parts depending on galvanic compatibility.

Start Your Specification

Explore our broader portfolio of overhead line fittings and insulator accessories on the

Damiano Products page, or share your drawings and load cases via our

Contact form for an engineered recommendation and a fast quote.

{

“@context”: “https://schema.org”,

“@type”: “BlogPosting”,

“headline”: “Insulator Hardware in India”,

“description”: “Damiano manufactures precision-engineered insulator hardware in India—ball & socket, tongue & clevis, yoke plates—tested as per IS 2486 and IEC 61284.”,

“author”: {“@type”: “Organization”,”name”: “Damiano”},

“publisher”: {“@type”: “Organization”,”name”: “Damiano”},

“mainEntityOfPage”: “https://adamiano.com/blog/insulator-hardware-india/”

}

{

“@context”: “https://schema.org”,

“@type”: “FAQPage”,

“mainEntity”: [

{

“@type”:”Question”,

“name”:”What is the difference between ball & socket and tongue & clevis?”,

“acceptedAnswer”:{“@type”:”Answer”,”text”:”Ball & socket is common for disc insulator strings due to quick coupling and universal articulation. Tongue & clevis offers alignment control and easy pin inspection.”}

},

{

“@type”:”Question”,

“name”:”How do I choose the KN rating?”,

“acceptedAnswer”:{“@type”:”Answer”,”text”:”Determine maximum mechanical loads (wind, ice, span, angles) and apply the utility’s safety factor. We map loads to hardware ratings and string geometry.”}

},

{

“@type”:”Question”,

“name”:”What about corrosion in coastal areas?”,

“acceptedAnswer”:{“@type”:”Answer”,”text”:”Specify higher HDG thickness or a duplex system (HDG + paint). Stainless or aluminium may be used selectively, ensuring galvanic compatibility.”}

}

]

}