The Critical Role of Overhead Line Hardware in Power Grid Reliability

While the towering steel structures and thick, shining conductors of the power grid command attention,

the true reliability of the system lies in the subtle but essential components that hold it all together:

overhead line hardware (OHL hardware).

Often overlooked, these fittings, clamps, insulators, and fasteners are the unsung heroes of energy infrastructure.

They are tasked with three concurrent, non-negotiable jobs: bearing extreme mechanical loads, ensuring perfect

electrical isolation, and protecting the conductive elements from environmental degradation.

A failure in just one piece of OHL hardware can result in catastrophic line outages, leading to costly repairs

and widespread service disruption. Understanding the categories, functions, and quality requirements of these components

is crucial for any project manager, engineer, or procurement professional in the energy sector.

The Core Functions of Overhead Line Hardware

Mechanical Support: Bearing the Load

This category includes all fittings designed to connect the conductor to the tower or pole structure.

They must withstand the combined forces of conductor weight, high tension, and dynamic wind and ice loads.

These fittings determine the mechanical life of the line.

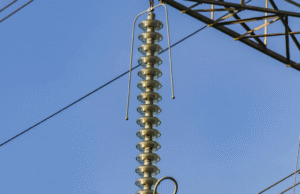

Electrical Isolation: Preventing Short Circuits

Insulators and related protective hardware prevent current from leaking from the conductor to the grounded

support structure. They are critical for preventing flashovers and maintaining the operational voltage of the line.

Conductor Protection: Mitigating Environmental Stress

These components are specifically engineered to mitigate the effects of natural phenomena, primarily conductor

vibration, ensuring the long-term structural integrity and fatigue life of the conductors themselves.

Category 1: Line Fittings and Conductive Components

Line fittings are components that attach directly to the conductor, providing either mechanical support

or electrical connection.

Suspension and Tension Fittings

Suspension Fittings (Tangent Clamps)

Used at intermediate, straight-run support points. They cradle the conductor and hold its vertical weight

but allow for some longitudinal movement. They are designed to minimize bending stress and often incorporate

an anti-corona ring in high-voltage applications to manage the electrical field.

Tension Fittings (Dead-End Clamps)

These are the anchor points, used at line ends, corners, and major angle changes. They must hold the full

mechanical tension of the conductor.

Compression Dead-Ends

Permanent, crimped fittings used for critical high-tension spans, ensuring the full rated breaking strength

of the conductor.

Preformed Helical Grips

A tool-less, easier-to-install option where preformed wires are wrapped tightly around the conductor,

distributing stress over a larger area.

Protection and Mitigation Hardware

Vibration Dampers (Stockbridge Type)

Strategically placed fittings consisting of weights connected by a messenger cable. They absorb the kinetic

energy of conductor vibration, dissipating it harmlessly. Without these dampers, the conductor’s lifespan

would be severely curtailed.

Armour Rods and Repair Sleeves

These reinforce the conductor at the point of attachment or are used to repair minor damage to conductor strands.

Internal Link: Discover our high-performance

Vibration Dampers and Protection Hardware

engineered for all ACSR and AAAC conductor types.

Category 2: Insulators and Electrical Isolation

Insulators ensure that the current remains confined to the conductor and does not leak into the ground

or surrounding air.

Main Insulator Types

Porcelain

Historically dominant, known for high compressive strength and durability.

Toughened Glass

Offers excellent dielectric strength and provides a clear visual indication of breakage.

Polymer/Composite

Lightweight, hydrophobic, and vandalism-resistant—ideal for distribution and medium-voltage applications.

The design of the insulator string dictates the creepage distance—the shortest path a leakage current

travels across the surface—critical for preventing flashover, especially in polluted or humid environments.

Category 3: Structural and Supporting Hardware

This hardware connects the fittings and insulators to the support structure. While it carries no current,

it bears the entire mechanical load.

Tower and Pole Accessories

- Cross-Arms and Braces: Provide horizontal separation and mounting surfaces.

- Clevises and Shackles: Connect insulator strings to clamps or the tower.

- Bolts, Nuts, and Washers: High-strength fasteners designed to prevent loosening from vibration.

The Imperative of Hot-Dip Galvanization

Most structural OHL hardware is steel or iron, making corrosion protection essential. Hot-Dip Galvanization (HDG)

applies a thick, sacrificial zinc layer that protects the steel for decades. Without HDG, steel components

deteriorate rapidly under atmospheric conditions.

Internal Link: Explore our certified Hot-Dip Galvanized

Frequently Asked Questions (FAQ)

What is the primary difference between suspension and tension fittings?

Suspension fittings hold the conductor’s vertical weight on straight runs and allow slight movement.

Tension fittings anchor the line at terminations or large angles and must withstand the full mechanical tension.

Why is Hot-Dip Galvanization (HDG) important for OHL hardware?

HDG prevents atmospheric corrosion by applying a sacrificial zinc layer to steel components. This ensures

structural longevity and reliability.

What are vibration dampers and why are they used?

Vibration dampers absorb wind-induced kinetic energy, preventing conductor fatigue and premature strand failure.

What are the three main types of insulator materials used in overhead lines?

The main materials are Porcelain, Toughened Glass, and Polymer/Composite. Polymer insulators are increasingly

preferred for their hydrophobicity and lightweight nature.

Ensuring Quality: Standards and Certification

Hardware performance cannot be judged visually; it requires strict testing. Reputable suppliers must provide

certification proving compliance with mechanical, electrical, and thermal requirements.

Key Standards

- IEC 61284: Requirements and tests for line fittings.

- IEC 60383: Testing for insulators.

- IS 2629 / ASTM A123: Standards for Hot-Dip Galvanization coating quality.

Rigorous testing—such as tensile strength tests for clamps, puncture resistance for insulators, and

salt-spray exposure for galvanized coatings—ensures reliable field performance under extreme conditions.

Adamiano provides meticulously designed and fully certified OHL hardware, forming the dependable backbone

of transmission and distribution networks worldwide.